Brick cladding design in the interior

External finishing work helps not only to make out the appearance of the building, but also to insulate it. Pretty beautiful brick cladding is in great demand.

All this is due to the various types of material and its properties.

The content of the article

Where can I apply a brick cladding

There are a wide variety of brick cladding options.

You can use it on any building and from any material:

- Shellfish.

- Building bricks.

- Foam concrete.

- Aerated concrete.

- Wood and so on.

Application area:

- The walls are lined with material and basement of the house and for this, various types of facing bricks are used.

- As a rule, for the basement in most cases a refractory facing brick is used.

- Thanks to its characteristics, it reliably protects the foundation of the house from freezing and weather conditions.

On the walls, you can use any type of facing brick.

Limitations for using brick cladding

A prerequisite will be that such outdoor work requires a foundation under them. This is due to the fact that brick is a heavy building material.

What you need to provide:

- The base can be poured right away, during the construction of the house or later, by pouring an additional foundation.

Tip. The primary and secondary foundation must be tied together.

- To do this, use reinforcement or a special wire mesh.

- The foundation is poured with concrete mortar of a similar composition as the main foundation.

Where it will not be possible to apply brick cladding:

- When there is no way to strengthen the old foundation or make a new foundation and tie it to the main.

- When the site may be sandy soil and the base of the structure is pile or columnar.

- When the ventilation gap will not be made.

The original design of the building with facing brick

Brick cladding design can be quite diverse. It all depends on the imagination of the designer himself.

As for the material itself, it has a wide range of sizes and shades, and will create the original appearance of any home.

Note. In most cases, red and white cladding bricks are used, the design can be using both of these shades of material. You can simply arrange the structure for decorative masonry.

What it is:

- After the brickwork is completed, all joints are processed with colored concrete. It is obtained by adding the coloring pigment of the desired color during the preparation process.

- There are options when the design of brick cladding implies the incomplete design of the structure with this material. Maybe just decorating the corners or basement of the house. The brick is very well combined with decorative plaster of various quality.

- It is also possible to use it with a plastic finish of the building or wooden. Only here it is worth considering that plastic or other facing material should be in the same plane with a brick.

This will provide an opportunity to reliably protect the building from moisture under the finish. - A beautiful brick lining implies the use of not only the standard shade of this material. You can make patterned masonry using a variety of shades of brick.

Thanks to this approach, any structure gains uniqueness and originality.

The photo shows examples of building design using facing brick.

Types of facing bricks

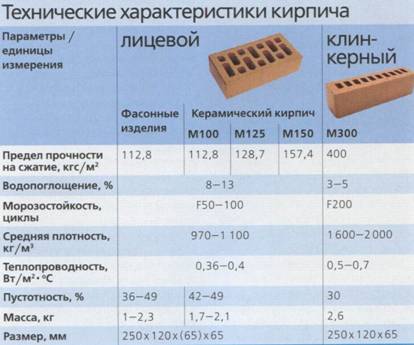

There are two types of facing bricks, which are divided into subspecies:

- Roasting.

- Unburnt.

Note. A simple brick for cladding goes without firing, and a beautiful facing brick with firing.

Calcined brick is divided into:

- Ceramic.

- Clinker.

- Hyperpressed.

- Silicate.

Unburnt are divided into:

- Fireproof.

- Road.

- Facial.

- Acid resistant.

Features:

- The price for each of these types is different, since there is a different technology for their manufacture.

- Brick is made without firing by pressing clay mass. And with firing, the brick is pressed and exposed to high temperatures.

- Fired facing bricks in most cases are hollow. Due to this, they conduct heat well, and protect the structure from the effects of cold climatic conditions.

- Unburned bricks are solid and rather heavy. This type of material is considered cold and for the use of this type of decoration will be required insulation and insulation of the house.

Advantages and properties of facing bricks

This material has excellent properties and technical indicators. It is very durable and able to withstand fairly strong mechanical and physical stresses.

Also facing brick:

- Moisture-resistant, as it does not absorb moisture and dirt.

- Practical - does not require specific care.

- Wear-resistant - does not lose its appearance throughout the entire life cycle.

- Durable - you can use brick cladding for 50-80 years.

- Frost-resistant - withstands very low temperature conditions.

- Fire resistant - not capable of being exposed to a direct source of fire.

- It withstands high temperature conditions and does not deform, since changes that may occur in its structure will not affect the strength and appearance of the material.

Throughout the entire period of use, the shade of the facing brick, which was originally, will not change, since the surface is not able to respond to sunlight and burn out at the same time.

Sometimes you can observe the appearance of salt on the surface of the brick from the front side. This indicates that the manufacturer could save on something in the manufacturing process of the material or that the mortar for masonry was made of low-quality cement or sand.

How to get rid of salt on a brick:

- There are a very large number of tools that cover the lining with a brush. Or you can just walk along the surface with an ordinary damp cloth.

Only here it is worth considering that after such work the brick can give an even greater amount of salt out to the surface.

Tip. When choosing a brick, you must ask the seller for a certificate of compliance with established standards.

An important role is played by the method of storing bricks. If he is constantly on the street and not in a protected state, then his properties and characteristics will gradually be lost.

Such material should be stored only in a warehouse at a certain temperature and only in a protected condition - covered with a film or a cardboard product.

Ceramic brick and its characteristics

This type of facing brick is most common in facade decoration. It can be either hollow or full-bodied.

Lighter, it is hollow and it does not require too expensive foundation.But with full-bodied material, it will be necessary to produce a very strong and reliable foundation under the lining.

Ceramic brick surface:

- Smooth.

- Glazed.

- With rough edges.

- Under the stone.

As for the shades, this type of material has a large assortment and thanks to this, the design of the facing brick can be simply unusual. Bricks with a glazed surface are often used to clad various ornaments and patterns.

Clinker brick and its advantages

- This type of brick is the most durable and most reliable. It is made from two grades of clay and is fired several times. Most often it is used for base trim.

- It can have not only directly proportional parameters. There are bricks with chopped ends and other decorative effects that help create a unique design of the building.

Hyperpressed facing brick and its characteristics

Hyperpressed brick differs from other types of such material in that clay and sand are not used in its production.

It is made of limestone and cement. The composition is pressed under very high pressure.

Brick has a wide range of shades and surface design, it can be:

- Smooth.

- Structural.

- Matt

- Glossy.

- With various imitations.

If such a brick cladding is used, the design of the structure will be very interesting.

Silicate facing brick

So:

- Silicate brick is a type of ceramic brick. Only it is slightly different in production technology.

It is also durable, but may in some cases have limitations in its design. - The most popular are white, red and yellow silicate bricks. They can also lay out ornaments and various panels on the wall of the building.

In its properties and characteristics, it is similar to any other type of this material.

Note. As a rule, this brick is full-bodied, but it does not have a very large mass. Therefore, it is very often used for cladding a house, its cost is low.

Brick house cladding

Not everyone in his life may have encountered brick masonry technology, but there is no particular difficulty in such work, and everything is done with your own hands.

In order to clad a house you will need:

- A solution of concrete in which coloring pigments can be added in order to create a decorative masonry.

- A trowel of the right size.

- Construction level for even laying of each cladding element.

Work:

- The most important thing is to connect the cladding and walls of the building itself.

For this, fittings mounted in the wall are used. When laying, it will be fixed with concrete mortar between bricks. - You also need to make a ventilation gap. Its size depends on the conductivity of the air masses with the main building material (from which the house is built).

There is a certain instruction for its calculation, which implies the use of all structure parameters to calculate the correct size of this gap.

Tip. If insulation is carried out on the house outside, this should also be taken into account in calculating the ventilation gap.

The process of laying the facing brick is shown in the video.

The main thing is to find a good master. And do not save on the quality of the brick. I used clinker brick to clad my wooden house and the house turned out to be a sight for sore eyes .. No worse than in English detective series (I always liked English cottages). And a very warm house, by the way. He made the guest out of ceramic, but of high quality and hollow. Also normal, but the view is still not the same.